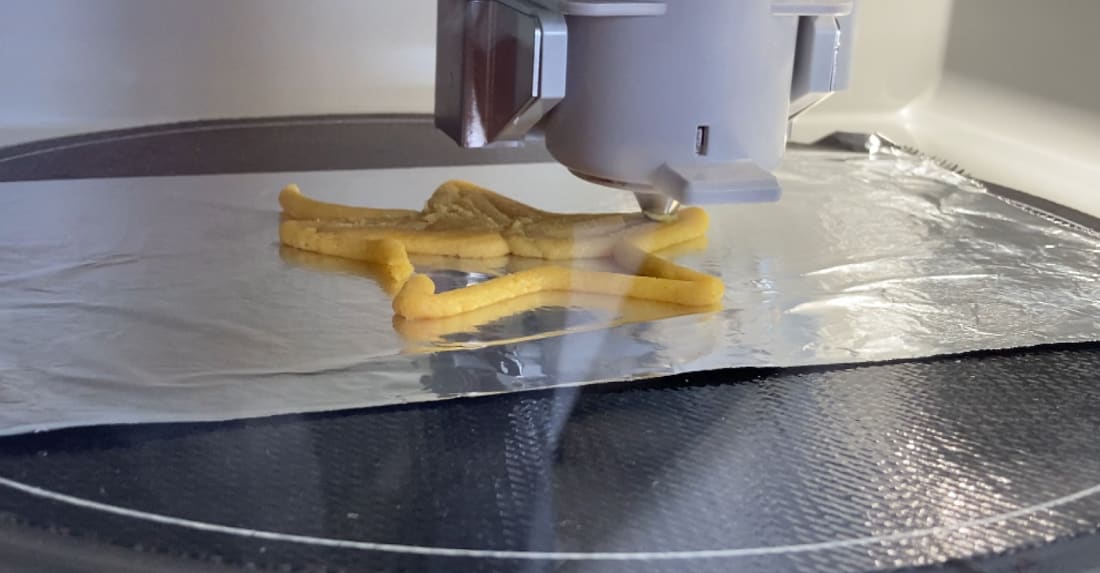

Jason Toon here, back from a visit to the future with another Shoddy Goods, the newsletter from Meh about consumer culture. Spoiler: tomorrow looks a lot like today. And in this case, it smells like oranges. When I told people I was going to watch some food being 3D-printed, they reacted as if I’d said I was going to have a cybernetic eye installed. They seemed to be picturing a pinkish-brown clump of cultured cells, oozing a liquid that is both blood and not-blood. I sensed a touch of discomfort, an uneasiness at the awful wonder of the swiftly arriving future. But it doesn’t feel like that in this 10th-floor laboratory at the Royal Melbourne Institute of Technology (RMIT). The substance being extruded by the Natural Machines Foodini isn’t some genetic soup; it’s a slightly experimental cookie dough. It isn’t being squeezed into a wad of quivering neo-meat, but into a star-shaped cookie like Grandma might make. After a few minutes of watching, it seems as exotic as the tile-roofed Australian suburbia stretching out below us. Which is to say, downright normal. This never happens when I put cookie dough in my HP printer at home “It wouldn’t even extrude” This team of Food Science grad students is looking at the feasibility of two practices: industrial 3D-printed cookie production, and the reuse of orange peels discarded from a local juicing facility and turned into powder. Both have potential sustainability benefits. “So you’re revalorizing the (orange peel) waste,” says Dr. Arianna Dick of RMIT, the academic supervisor of the project, who Shoddy Goods readers may remember from our search for sugar-free candy bars, “and at the same time the 3D printer itself is a sustainable technology. Compared to molds that you would use at the industrial level to create similar shapes, a 3D printer uses the exact amount. So it will only deposit the amount needed for the shape, whereas in molding, you need to cut whatever is left outside of the mold.” We bring up some 3D models on the operating touchscreen of the Foodini, a countertop 3D printer about the size of the first microwave my family had in the ‘80s. Some of the models come pre-loaded, some were created by this team, and some are shared by a community of 3D food printers. The Foodini in a totally normal kitchen with multiple baskets of apples The project initially tested three different doughs - one with 5% powdered orange peel, one with 10%, and one with 20% - against a control dough with none. But now it’s down to two test subjects. “The 20% one wasn’t even able to print because of how thick the powder made it,” says Master’s candidate Aloys Duhamel. “Thick and dry, yeah,” agrees fellow grad student Prayush Agarwal. “It wouldn’t even extrude out of the nozzle.” If you’re ever worried that the future’s coming at you too fast, just remember: even the most cutting-edge technology can still be clogged up by overly thick cookie dough. Duhamel loads some of the 5% mixture - “our favorite,” says lab supervisor Dr. Uzma Sadiq - into the Foodini’s capsule, chooses a star design, tweaks a few other settings, and hits “print”. Off it goes, laying down lines of dough into the (not extremely fine, it must be said) shape of a star. The delightful whiff of orange zest hangs in the air. It’s almost homey, a far cry from the sci-fi vibe of 3D-printed steaks. This is just one of hundreds of 3D-printed food experiments happening around the world at any given moment. The small, incremental benefits of processes like this won’t make breathless headlines. But in aggregate, they’re more likely to drive the spread of 3D food printers than those futuristic moonshots. Meal delivery in space? If it seems like 3D food printing at this point is more about aesthetics than sustenance, Dr. Dick reminds me that when it comes to food, the two are inseparable. She cites the work of a company like Gastronology: for dysphagic patients who can only swallow soft foods, giving that food an appealing color, shape, and texture isn’t trivial. 3D printing can also address the social-connection aspects of food for people in space and other isolated environments. As a 2024 report in the journal Life Sciences in Space Research puts it: “In such long-duration human-crewed space missions, under microgravity conditions and exposure to space, psychological factors heavily affect food consumption patterns. Therefore, there has been a surge in research funding for developing products and methods that offer safe, nutritionally balanced, and delightful food options. 3D food printing could be a creative solution for such requirements.” Dr. Dick cites “space-ready meals” as another growing area of study. “Maybe someone can, from Earth, send a (meal as a) message to a person in space” as a form of sharing a familiar dinner together, she says, adding that an upcoming experiment by an RMIT student will be examining that possibility. Personalized food is another emerging frontier; after all, not everyone’s nutritional needs are the same. “Another interesting thing is coupling the printer to software where you can tell the software, this is my activity today, this is the energy,” Dr. Dick says. “It will calculate how many calories you need and different nutrients. And based on that, it can propose a snack or something like that.” Do not consume entire stack in one bite If the industrial applications of 3D food printing are still in the exploratory stages, that goes double for its use in the home. While models like the Foodini are intended for both home and commercial use, Dr. Dick says they cost too much and can do too little to be a winning proposition for consumers - yet. “Several design, price, and functionality thresholds must be met,” she says. “They must be highly user-friendly, with intuitive operation, minimal setup, and the ability to handle a variety of food materials without frequent adjustments or troubleshooting. They should be compact enough to fit comfortably on a kitchen counter. In terms of price, 3D food printers must become more affordable... [and] 3D food printers should be able to produce meals within minutes, ideally integrating cooking features.” Consumer 3D food printers aren’t there yet. I think again about early microwaves. The first home microwaves were introduced in 1955: bulky, basic, and reeaaallly expensive. Widespread consumer adoption took decades as the design slowly improved and the prices slowly fell. But when that curve lifted off, it climbed fast: from 1% of US households in 1971, to 25% in 1986, to upwards of 90% by 1997. Back in the lab, I watch Duhamel, Agarwal, and fellow grad student Emilie Jabu run some of the baked cookies through a battery of tests to objectively color, texture, hardness, and other properties. These are all standard food science procedures (which didn’t keep me from geeking out about the cookie-breaking machine). The little cookie extruded by the Foodini is the first 3D printed food I’ve ever seen. It seems awfully humble for a herald of revolution. But as the technology gets better and better, and as scientists like these RMIT students keep exploring the possibilities at the intersection of nutrition, psychology, manufacturing, and design, I’d be surprised if it’s the last. Behold the future! Jason says thanks to Dr. Arianna Dick, Dr. Uzma Sadiq, Prayush Agarwal, Aloys Duhamel, Emilie Jabu, and the Royal Melbourne Institute of Technology for letting me stumble around their lab and ask stupid questions. Weirdly, I guess I own a 3D food printer - I got the Pancakebot as a gift 9 or 10 years back. I can’t say I’ve made a lot of use of it lately, though, but it was fun to see what the Meh logo looked like in pancake form. Have you ever owned any fun food gadgets or toys? Seen any fun food tech you wish you could try out? Let’s talk in this week’s Shoddy Goods chat. Enjoy these nutritious stories extruded from the Shoddy Goods infotainium: |